Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

Material: Carbon steel Color: Blue

Processing capacity:1-3T/H

1-3T/H type palm fruit oil production linePalm fruit accounts for 55% -60% of the fruit string.

1-3T/H type palm fruit oil production line

Palm fruit accounts for 55% -60% of the fruit string. Palm fruit has two parts: the skin (pulp) and the kernel. The flesh accounts for 50% -55% of the fruit volume, while the kernel accounts for 45% -50% of the fruit volume. The fruit pulp contains 46% -50% oil (red oil),

Fruit kernels contain 45% -50% oil (white oil). The processing techniques of palm pulp oil and kernel oil are different, and the composition and properties of fatty acids are also different.

Our company mainly produces a complete set of equipment for palm oil production with a processing capacity of 3-5 tons per day.

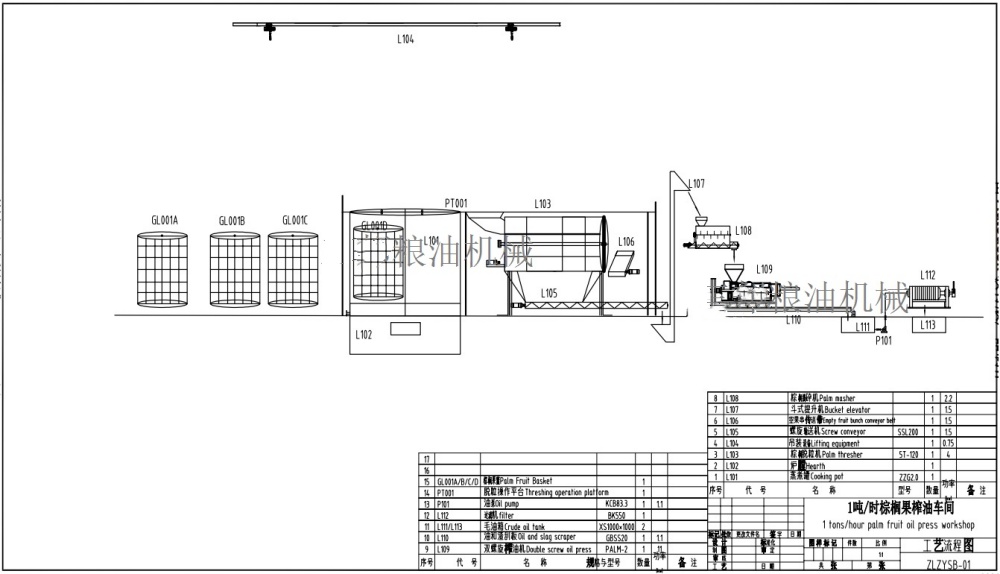

Process flow:

1. Palm fruit skewers - enzyme killing, fruit steaming - threshing - pressing - filtration - dehydration - crude palm oil (red oil) - refining

1.1. Defatted fruit residue - kernel residue separation - drying - crushing - pressing - crude palm kernel oil (white oil)

Process description:

1. The inactivation of enzymes in palm fruit is to inhibit the lipolytic enzymes in oil. The presence of lipolytic enzymes will cause the decomposition of palm oil to produce free fatty acids, leading to an increase in acid value. After heating to inactivate the enzymes, fat decomposition is controlled to ensure quality.

2. The process of enzyme inactivation causes hydrolysis and softening of the fruit pulp, while creating favorable conditions for subsequent oil extraction and fabrication.

3. Palm ears are threshed using a drum type thresher.

4. Palm fruit can be divided into two parts after being pressed: a mixture of oil, water, and solid impurities, and fibers and fruit kernels.

5. Palm crude oil should be dehydrated and filtered in a timely manner to improve its purity and facilitate storage.

Technological advantages:

1. Our company's self-developed and designed fruit peeler has made various improvements compared to the old style fruit peeler in terms of drum diameter and speed. The fruit can be peeled before and after enzyme killing, and the fruit damage rate is low.

2. Our company has specially designed an enzyme killing and fruit steaming integrated machine for small-scale palm fruit oil production lines, which increases working pressure and shortens the time for enzyme killing and fruit steaming. The fruit steaming process uses lifting equipment to reduce manual operation and risks.

3. Using a palm specific oil press.

4. Modern dehydration equipment, electronic temperature control, good dehydration effect, and low equipment cost.

5. The difference between this process and conventional processes is the combination of enzyme killing and fruit steaming, purification, and dehydration filtration, which not only improves productivity but also reduces equipment investment.

Notes:

1. Fresh fruit skewers should be promptly treated with enzyme to prevent an increase in acid value.

2. The temperature for enzyme inactivation is not easily too high and should be maintained around 100 degrees Celsius.

3. Palm crude oil should not be left for too long and should be dehydrated or refined in a timely manner.

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.