Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

Material: Carbon steel/wear-resistant material

Processing capacity:800-1000KG/H

Palm-2 double spiral palm fruit oil machineIngredients: fresh palm fruit skewersPalm oil output rate: 35-45%from palm fruit

Palm-2 double spiral palm fruit oil machine

Ingredients: fresh palm fruit skewers

Palm oil output rate: 35-45%from palm fruit skewers

Production capacity: 1-5T/h palm fruit skewers

Main process:

Raw Material Received Workers-Sterilization Station-Labramids-Digestive Compression Station-Oil Clarity Station-Ren recycling Station

Bid reception station:

The palm oil processing plant was started after harvesting the palm fruit skewers, and it was sent to the palm oil plant for processing. During the harvest process, carefully handle fruits to prevent scratching, because scratching will reduce the quality of extract oil.

Sterilizer:

The sterilization process follows the process of using a large amount of heat to cook fruits. In this palm oil processing station, the enzymatic response has also stopped, preventing hydrolysis and automatic oxidation, and the skin's skin (skin skin) is also weakened, which is easier to extract oil from the fruit. This process can be completed by baking/smoking after the decarning process or steam/boiling before the decarning process.

Persia station:

Then the fruit skewers are de -particle, and the small fruit is separated from the fruit skewers in the drum. It can be completed by manual or mechanical manual or mechanical by using palm oil processing machinery -dealer/decarorages. The loose fruits are then transported to another palm oil processing machine -cooking machine. The empty fruit skewers are separated and returned to the plantation or used as a fuel in a boiler.

Digestive station:

Then digestion fruit in the digestive. This process includes crushing fruits and heating flesh before the oil is pressed. To extract oil to the greatest extent, heating is important.

Use dual screw palm fruit oil press:

Then clarify the oil and screen impurities in this process, so as to remove large fiber solids and dirt from crude oil. Then add the water to the crude oil to improve the separation process. After the sieve is sieved, it is obtained, but it still contains small solids and water. Remove water by introducing steam (increased temperature in the tray) in the tray. The fine solids in the oil are eventually removed during precipitation, which separates the oil from the mud. Each ton of palm fruit is treated with about 163 kg of oil.

Benevolent Recycling Station: The pressed cake (fiber & nuts) is transported to the fiber separation system for fiber & nuts separation, and the separated nuts are sent to the nut warehouse temporarily.

The palm kernels are crushed by the ripple grinding machine to obtain a mixture of palm kernels and shells.

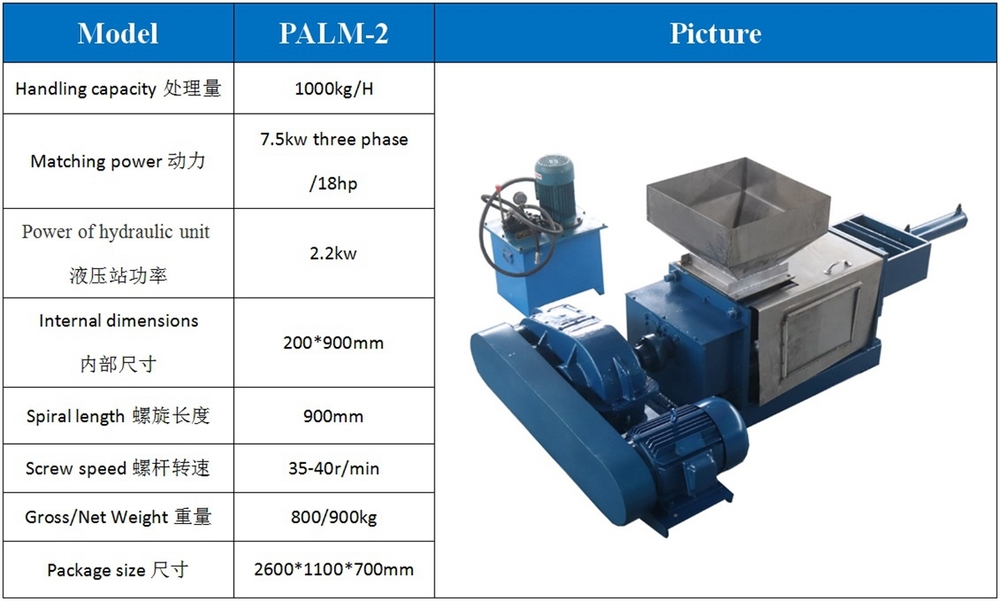

Device parameters:

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.