Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

Material: carbon steel/wear-resistant material Color: blue/yellow

Processing capacity:2-3T/D

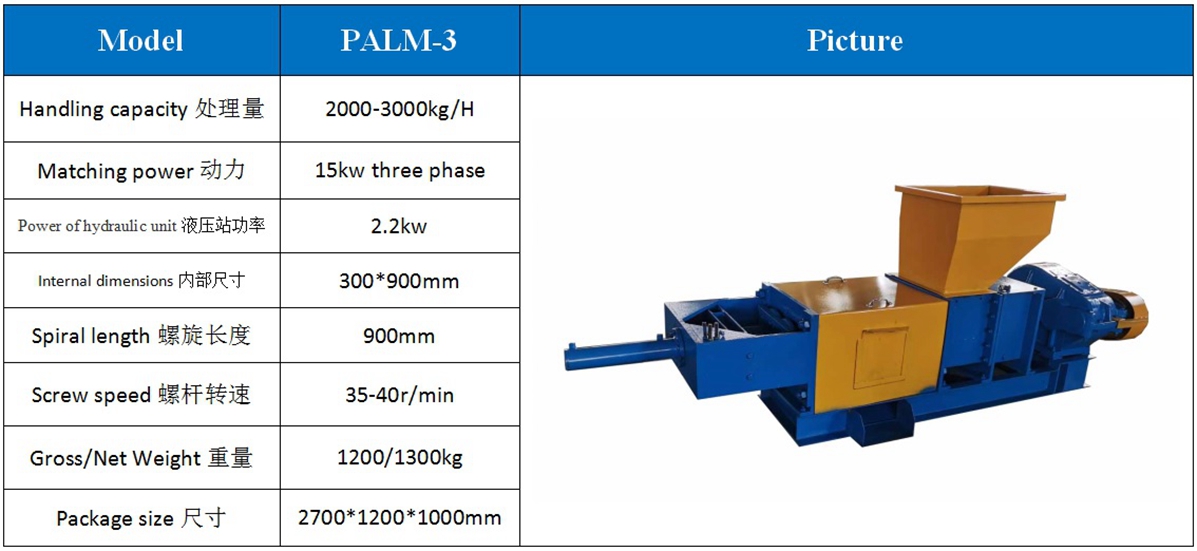

Model: PALM-3Type: Palm oil pressSpecifications: 2-3t/dMaterial: carbon steel/wear-resistant materialColor: blue/yellow

Product Details

PALM-3 double screw palm oil press

share to:

PALM-3 double screw palm oil press

Model: PALM-3

Type: Palm oil press

Specifications: 2-3t/d

Material: carbon steel/wear-resistant material

Color: blue/yellow

Brand: TOP Machinery

No.: T008

Product Details

PALM-3 double screw palm oil press

Ingredients: fresh palm fruit bunches

Palm oil output rate: 35-45% comes from palm fruit bunches

Production capacity: 3-5T/H palm fruit bunches

Main process:

Raw material receiving section--sterilization station--threshing section--digestion and pressing station--oil clarification station--kernel recycling station

Bundle reception station:

The palm oil processing plant starts after harvesting the palm fruit bunches and sends them to the palm oil mill for processing. During the harvesting process, the fruit should be handled carefully to prevent bruising, which can reduce the quality of the extracted oil.

Sterilization station:

Sterilization follows a process that uses large amounts of heat to cook the fruit. In this palm oil processing station, enzymatic reactions are also stopped, preventing hydrolysis, auto-oxidation, and the outer skin of the fruit (exocarp) is weakened, making it easier to extract oil from the fruit. This process can be done by roasting/smoking which takes place after the threshing process or by steaming/boiling which should be done before the threshing process.

Threshing station:

The fruit bunches are then threshed and the small fruits are separated from the bunches in a drum. It can be done manually or mechanically by using palm oil processing machinery - thresher/thresher. The loose fruit is then conveyed to another palm oil processing machine - the digester, and the empty fruit bunches are separated and returned to the plantation or used as fuel in boilers.

Digestive station:

The fruit is then digested in the digester. The process involves crushing the fruit and heating the pulp before the oil is extracted. To maximize oil extraction, heating is important.

Using twin-screw palm fruit oil press:

The oil is then clarified, during which impurities are screened to remove large fibrous solids and dirt from the crude oil. Water is then added to the crude oil to improve the separation process. After sieving, crude crude oil is obtained, but it still contains fine solids and water. Water is removed by introducing steam into the coil (increasing the temperature in the coil). The fine solids in the oil are eventually removed during sedimentation, thus separating the oil from the sludge, yielding approximately 163 kilograms of oil per ton of palm fruit processed.

Kernel recycling station: The pressed cake (fiber & nuts) is transported to the fiber separation system for fiber & nut separation, and the separated nuts are sent to the nut warehouse for temporary storage.

The palm kernel nuts are crushed in a corrugated mill to obtain a mixture of palm kernels and shells.

Device parameters:

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.