Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.

Material: sheet zinc Color: galvanized

Processing capacity: 50KG/H

The oil machine extracts 10 kg per time and takes a short time (4~~6 minutes per time).

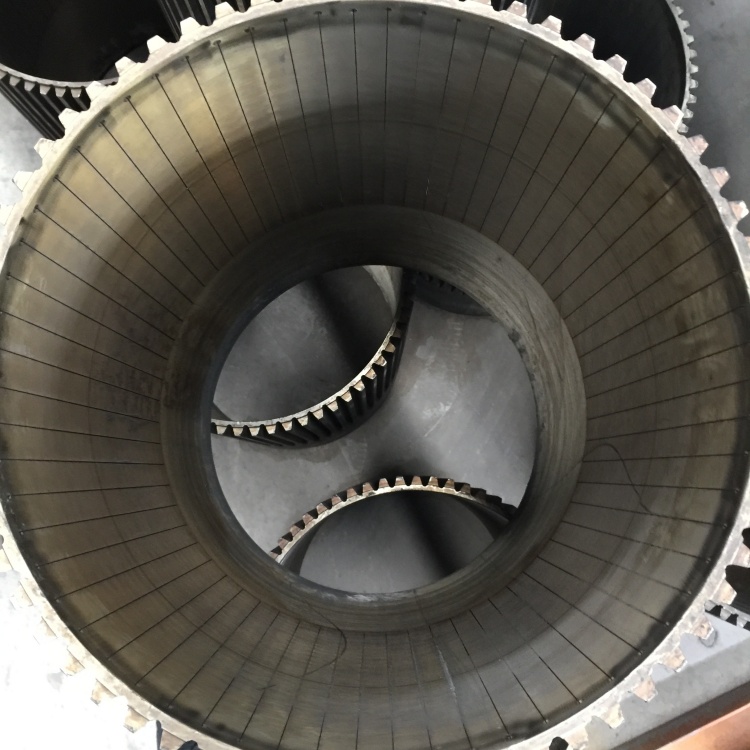

6YZ-230 hydraulic oil press

Scope of use

The fully automatic hydraulic oil press produced by our company is a small oil press that is easy to operate, has a high oil yield, and requires less replacement of wearing parts among mechanical oil presses. It is currently an advanced equipment that replaces the manual operation of small sesame oil grinding. The oil machine extracts 10 kg per time and takes a short time (4~~6 minutes per time). It is especially suitable for the consumer psychology of citizens in large and medium-sized cities who spend money to buy real products (oil → pressing → sesame oil). In rural areas Townships can guarantee fast processing of incoming materials and get their own oil, which is known as safe and pure oil.

The main oil crops processed by this machine are: sesame, walnut kernels, pine nuts (with good peeling effect), almonds, perilla, flax and other oil crops with high oil content.

6YZ series hydraulic oil press parameters:

TYPE | 6YZ-180 | 6YZ-230 | 6YZ-260 | 6YZ-300 | 6YZ-320 |

Processing capacity | 3 kg / time | 7 kg / time | 11 kg / time | 15 kg / time | 20 kg / time |

Pressing time | 6-8 Minutes | 6-8 Minutes | 6-8 Minutes | 6-8 Minutes | 6-8 Minutes |

Working pressure | 60MPa | 60MPa | 60MPa | 60MPa | 60MPa |

Nominal pressure | 1600KN | 2200KN | 2600KN | 3000KN | 3500KN |

Motor power | 1.5kw | 1.5kw | 2.2 kw | 3 kw | 3 kw |

Electric-heating power | 1 kw | 1 kw | 1 kw | 2kw | 2 kw |

Electric heating temperature range | 30-100℃ | 30-10℃ | 30-100℃ | 30-100℃ | 30-100℃ |

Net weight of equipment | 530kg | 880kg | 1200kg | 1600kg | 2000kg |

External dimensions | 700*650*1100mm | 800*750*1400mm | 900*900*1450mm | 1000*1000*1500mm | 1100*1100*1600mm |

Operating procedures for hydraulic presses

Precautions before starting up:

The pressure of this machine is up to 55 MPa (it has been adjusted before leaving the factory, please do not change it without permission).

Clean the inside of the fuel tank and add enough hydraulic oil.

Check if the bolts in various parts of the pump body are loose.

Check if the circuit connection of the meter box is correct.

1. Preheating is necessary before each oil extraction, otherwise it will affect the oil yield. Preheating temperature: 50 ℃ -70 ℃ in summer and autumn, and 70 ℃ -90 ℃ in winter and spring. The preheating system is automatically controlled without the need to turn off the temperature control switch.

2. Hold the handle of the upper top plate and open it at a 160 ° angle to the working position. Place a cushion at the bottom of the pressing and boring machine, and lower the piston to the bottom for later use.

3. Before each oil extraction, run the machine empty 1-2 times. If the hydraulic oil becomes thicker in winter or spring, run the machine empty for 5-10 minutes until the hydraulic oil becomes thinner before operation, otherwise it will affect the oil extraction speed.

4. Drain the fried oil and put it into a press boring machine to prepare for pressing.

5. Place a cushion on the upper end of the oil material for pressing and boring, place the pressure plate on the upper end face of the pressing and boring machine, and push it flat into the pressing and boring machine. If there is less oil, the oil can be raised when starting up, always keeping it lower than the upper surface of the pressing and boring machine; Otherwise, the top plate cannot be closed. Lift the handle of the manual valve and start the pressing.

6. This hydraulic press belongs to an ultra-high pressure system and must be operated by a dedicated person during operation. The main engine must not leave people during the boosting process. When the pressure is expressed to 55 megapascals, the main motor should automatically stop working. Otherwise, the power should be immediately turned off, and the pressure gauge should be checked for damage, malfunction, and AC contactor damage. If there is any damage, it should be replaced immediately and checked for accuracy before starting up for use.

When the pressure gauge rises to 55 megapascals, the electrical control system automatically stops. When the boring pressure drops to 45 megapascals, the electrical control system automatically opens, and the pressure gauge pressure rises again. Generally, it can be repeated twice. When there is no oil leakage from the oil gap of the boring, it indicates that the oil has been completely squeezed.

8. Turn off the machine, hold the handle of the manual control valve and press it down to lower the oil in the boring process to 10 millimeters from the top. Lift the handle of the manual control valve and open the top plate.

9. Turn on the machine to raise the oil cake. When the hole plate is higher than the upper end face of the press boring, turn off the machine, remove the partition plate and upper cushion, and take out the oil cake. Please note that when the hole plate is being pressed and bored, it must be immediately shut down, otherwise the piston will be knocked off. If the piston is accidentally knocked off, the nut, upper top, and material bucket should be removed in sequence, and the piston should be placed in the correct position before it can be restarted for use.

10. Press down the handle, lower the piston to the bottom, and prepare for the second press.

Please feel free to write down your requirement in the form below. We will reply you within 24 hours.

We will strictly protect the privacy of users'personal information and never disclose it.